In the United States, more than 90% of paved roads are made of asphalt, which is made of non-renewable materials such as petroleum. One way to make paving more sustainable is to recycle old sidewalks. When a road crashes and needs to be repaved, the transport agency can recycle its old pavement into reusable material, called recycled asphalt pavement or rap. This approach reduces carbon emissions and preserves natural resources.

In the United States, nearly 95% of new asphalt pavement projects are included in RAP.

However, researchers are less aware of RAP's long-term safety and durability than they know about new sidewalks.

So, can engineers make the road more sustainable without compromising safety? As civil engineering researchers at the University of Tennessee University of Knoxville, we are working with the state Department of Transportation to help answer this question.

Rap and friction

The asphalt pavement consists of asphalt binder and aggregates. Asphalt binders are usually sticky and black oil materials that act as glue to put sidewalks together.

Aggregates are solid materials such as gravel, gravel or sand. Sidewalk manufacturers cover these aggregates with asphalt to combine them together and create durable road surfaces. But both materials are non-renewable.

One way to reduce the demand for new aggregates is to recycle old sidewalks. The contractor uses a milling machine to grind existing sidewalk surfaces. The milled material was then reused: the old aggregates and asphalt binder became part of the new mixture. These old materials are usually mixed with new adhesives and other aggregates to ensure they perform well.

Why study the characteristics of rap?

One challenge with RAP is that its characteristics vary widely. Raps usually look black as they are completely covered in asphalt. Researchers have difficulty examining them visually to identify aggregate type, shape, or texture. But we developed a test program to measure these properties.

The ability of this road to grab a tire, called anti-slip properties, prevents the vehicle from slipping or hydraulic balls in wet conditions. Anti-slip resistance is usually quantified by measuring the coefficient of friction between the tire and the pavement surface.

Pavement friction is a force that resists movement between vehicle tires and the sidewalk surface. More friction means the vehicle is less likely to slip.

It is important to understand the properties of RAP related to slip resistance, as these properties can affect the safety of the sidewalk, especially in wet conditions.

Nearly 75% of weather-related accidents occurred on wet sidewalks. At low speeds, most of the anti-slip between the tire and the sidewalk comes from the aggregate texture.

Most friction studies have tested new aggregates. Rap needs to maintain good friction properties in order to be as safe as the original one, but until now, researchers have not fully investigated whether to do so.

How we study the characteristics of rap

Our research team developed a two-step process to better understand the safety performance of rap. First, we extract aggregates from RAP. We then measured the frictional properties of these aggregates because they play a key role in pavement resistance.

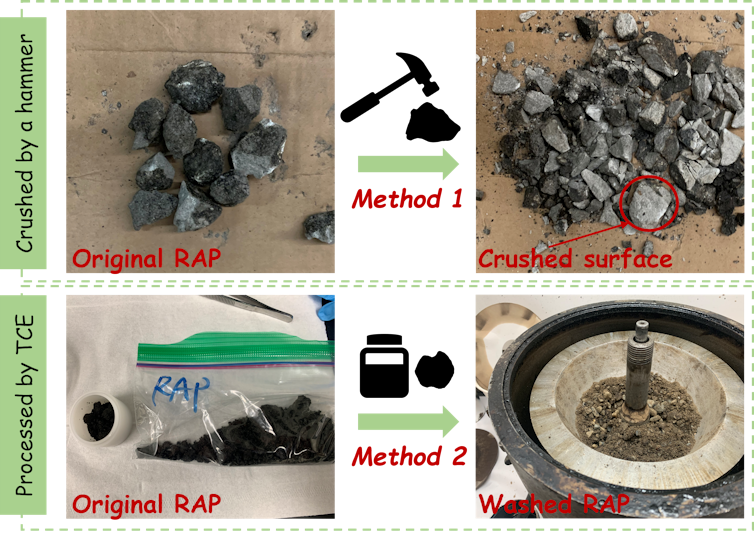

To remove the black asphalt coating and expose the actual surface of the aggregate, we used two simple methods. The first is a mechanical method where we use a hammer to crush RAP to expose the surface inside. The second is the chemical procedure, where we use solvents to dissolve the bitumen and leave the aggregates for further testing.

Once we clean the aggregates, we analyze their chemical composition and understand their relationship with friction. One factor we look for is hardness in minerals. Hard minerals such as silica will provide better friction as they will maintain better texture over time rather than exhausted within traffic.

We also use a polymer image measurement system that takes high resolution images and analyzes shapes, angles - the clarity of aggregate particles of aggregates - and the surface texture of aggregates. These characteristics are directly related to slip resistance.

Understanding the frictional properties of RAP-, specifically how silica content affects slip resistance - helps engineers determine whether the RAP mixture is suitable for the road curve or intersection safety. These insights can guide how much and where the rap transmission department can use without compromising security. We hope our research will enable solutions that reduce carbon emissions, save natural resources and ensure road safety over time.