Every time you use your phone, turn on your computer, or listen to your favorite music on Airpods, you rely on key minerals.

These materials are tiny components that power modern life. From lithium, cobalt, nickel and graphite in batteries to coagulants in telecommunications systems, constant connectivity is achieved, and key minerals act as essential vitamins for modern technology: smaller in size but critical to function.

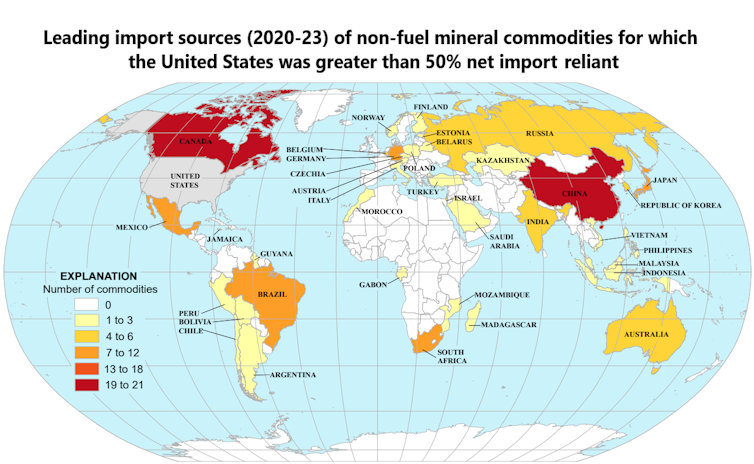

However, the United States depends to a large extent on the import of most critical materials. In 2024, the United States imported 80% of the rare earth elements it uses, 100% of coagulation and natural graphite, and 48% to 76% of lithium, nickel and cobalt, to name just a few.

[embed]https://www.youtube.com/watch?v=wooz8xfqus4[/embed]

Rising global demand, high import dependence and growing geopolitical tensions have made critical mineral supply an increasing concern for national security – and one of the most urgent supply chain challenges of our time.

This raises the question: Can the United States process more critical minerals at home?

As a geochemist who leads the Georgia Tech Center for Critical Mineral Solutions and an engineer focusing on energy innovation, we have been exploring options and barriers to critical mineral production in the United States.

What prevents the production of key minerals at home?

Let's take a look at the rare earth elements.

These elements are crucial for modern technology, electric vehicles, energy systems and military applications. For example, New Mountain is crucial for making strong magnets use in computer hard drives, lasers and wind turbines. Gadolinium is crucial to MRI machines, and SAAMARIUM and PERIUM play a key role in nuclear reactors and energy systems such as solar and wind.

Despite their names, rare earth elements are actually not uncommon. Their concentrations in the Earth's crust are comparable to more common metals such as zinc and copper.

However, rare earth elements usually do not occur in easily accessible, economically viable mineral forms or in advanced sediments. As a result, identifying resources with sufficient concentration and large capacity is crucial to achieving their economic production.

Currently, there are only two domestic rare earth mining sites in the United States: Georgia and California.

In southeast Georgia, rare earths are being produced as a by-product of heavy mineral sand mining, but the rare earth concentrates produced are shipped out of the state and then used abroad to refine materials used in renewable energy technologies and permanent magnets.

Another location is located in a mountain pass in California, where hard rock mining extracts a rare earth carbonate mineral called bastnaeite. Again, many of the materials were sent abroad for refining. As a result, the entire supply chain – from mining to end use – extends across continents.

Meeting the U.S. demand for rare earth elements and other critical minerals requires not only opening up new mines. It will require the development and extension of new technologies as well as building handling operations.

Historically, due to environmental impacts, energy demand and regulatory restrictions, processing has taken place overseas.

Potential but long road to the new mine

Investment in exploration activities in key minerals is increasing rapidly in the United States

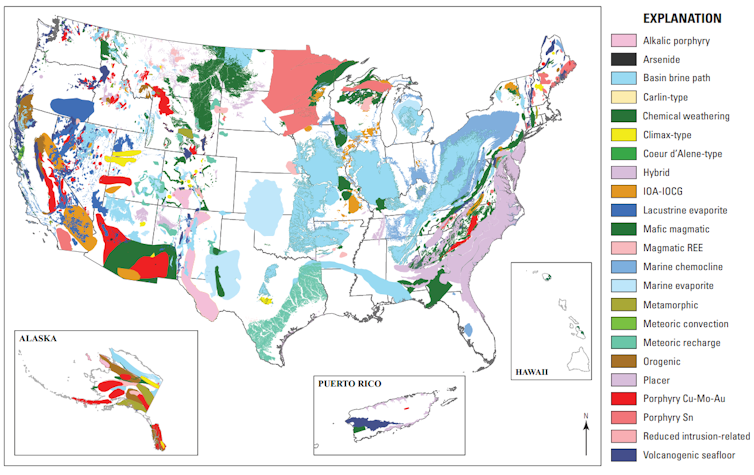

In 2017, the U.S. Geological Survey launched the Earth Map Resource Program - known as Earth MRI - to identify potential sources of critical minerals in the country.

For rare earth elements, some areas that seem promising have many chemical weatherings in which rocks containing rare earth elements break down by reacting with water and air. Several of these locations are being explored, including those in Wyoming and Montana.

However, determining a resource is different from producing it.

From exploration to production, traditional mining can take ten to ten years in the United States, the second longest timetable in the world. While this timeline may change in the case of the current government, companies may still face major uncertainties related to licensing, infrastructure development, and in some local community opposition. Managing environmental impacts such as air and water pollution, high water consumption and energy use can further increase costs and extend project timelines.

Given that the above exploration projects are still in the early stages, the United States needs additional parallel efforts to bring resources to the market at an accelerated pace.

Dig out the materials we have mined

One of the fastest ways to increase our rare earth production may not require digging new holes in the ground - instead returning to old ones.

The Atlantic Coast region stands out on the Earth's MRI map and is a particularly promising area. Even better, the region has established extensive mining activities and mature infrastructure to make it faster to market.

Georgia's mineral sand deposits are rich in titanium, zirconium and rare earth elements. Titanium and zirconium – both used in aerospace, energy and medical applications – have been mined in Florida and Georgia. In southeast Georgia, rare earth elements from these heavy mineral sand have been found to be recycled into rare earth concentrates.

[embed]https://www.youtube.com/watch?v=jl-svrk1spk[/embed]

Kaolin is a white clay made of paper, paint and porcelain that has been mined in Georgia for more than a century and may also contain rare earth elements. Georgia generates more than 8 million tons of kaolin each year, making it a leading producer and large exporter in the United States. This also carries millions of tons of mining and processing residues or so-called tailings.

Recent studies have shown that extracting rare earth elements from tailings has great potential.

The tailings have been mined and sat on the ground. No drilling or explosion required. This means existing infrastructure, faster timelines and lower costs and compared to new mining operations.

Technological innovations such as biopenetration, ligand-based extraction, separation, and electrochemical separation are now making mining heritage waste possible. New processing facilities can be built near existing kaolin or heavy mineral sand operations or previous mines and bring materials to market in a few years instead of decades.

The future of waste mining

This approach is part of a broader strategy called “waste mining,” “urban mining,” or “anthropogenic cycles of excavation.”

It involves restoring critical minerals from existing waste streams such as mine tailings, coal ash and industrial by-products. It is also part of building a circular economy in which materials are reused and recycled rather than discarded.

The United States has the potential to catalyze new domestic supply chains for materials essential for national security and technology. Waste mining and recycling are a key part of ensuring the long-term sustainability of these supply chains.